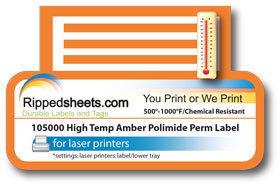

High Temperature Amber Polyimide Permanent Adhesive Labels

#105000 - Polyimide Permanent Labels

This high temperature Amber Polyimide with Permanent Self Adhesive label material (500°-1000°F) was designed for barcode or alphanumeric identification of printed circuit boards or related electronic components. Please read Technical Specifications Link for all Specifications by Printer Type.

105000 Amber Polyimide with Permanent Self Adhesive has a high-performance chemical resistant acrylic adhesive that may be printed on a small black and white laser printer. Material durability is subject to chemicals, cleaners, heat and saponifiers used in PCB manufacturing.

| Part Number | Label Size (in) | Label Size (mm) | Labels Per Sheet | Sheets Per Package |

|---|---|---|---|---|

| 105000-1 | 0.25″ × 0.25″ | 6.35 mm × 6.35 mm | 936 | 11 |

| 105000-2 | 0.30″ × 0.375″ | 7.52 mm × 6.53 mm | 836 | 12 |

| 105000-3 | 0.375″ × 0.375″ | 9.53 mm × 9.53 mm | 400 | 25 |

| 105000-4 | 0.50″ × 0.437″ | 12.70 mm × 11.10 mm | 286 | 35 |

| 105000-5 | 0.65″ × 0.25″ | 16.51 mm × 6.35 mm | 152 | 66 |

| 105000-6 | 0.65″ × 0.20″ | 16.51 mm × 5.08 mm | 480 | 21 |

| 105000-7 | 0.80″ × 0.25″ | 20.32 mm × 6.35 mm | 304 | 33 |

| 105000-8 | 0.80″ × 0.50″ | 20.32 mm × 12.70 mm | 152 | 66 |

| 105000-9 | 1.0″ × 0.25″ | 25.40 mm × 6.35 mm | 266 | 38 |

| 105000-10 | 1.0″ × 0.375″ | 25.40 mm × 9.63 mm | 175 | 58 |

| 105000-11 | 1.0″ × 0.50″ | 24.4 mm × 12.70 mm | 133 | 76 |

| 105000-12 | 1.50″ × 0.25″ | 39.10 mm × 6.35 mm | 190 | 53 |

| 105000-13 | 1.875″ × 0.25″ | 47.63 mm × 6.35 mm | 156 | 64 |

| 105000-15 | 3.0″ × 0.375″ | 76.20 mm × 9.35 mm | 50 | 100 |

Pricing

Pricing and shipping quotes available on request. Please contact us for more information.

Let us print for you! Full Color Printing available.

Specifications

TDS No. 105000

Effective Date: 02/21/2000

Description:

Polyimide film with a high performance printable topcoat and a high temperature acrylic pressure sensitive adhesive.

Designed for applications requiring excellent solvent resistance and high temperature performance, like top side and bottom side of printed circuit boards.

Designed to withstand the various fluxes, molten solder dips or solder reflow methods, and cleaning solvents encountered in the manufacture of printed circuit boards.

Greenish/amber in color.

If you are looking to meet Mil-Std, then you must purchase 105000 sheets and print on a dot matrix printer using Brady Series R2000 dot matrix ribbons which meet the requirements of:

- MIL-P-55110D General Specification for Printed Wiring Boards

- MIL-M-81531 Marking of Electrical Insulating Materials

- MIL-STD-202F Method 215J Resistance to Solvents

(105000 printed with laser print does not meet these requirements)

Details

- Thickness: 0.111 mm

- Adhesion to Stainless Steel: 24 hour dwell, 35 oz/in

- Adhesion to Epoxy PC Board: 24 hour dwell, 35 oz/in

- Adhesion to Textured ABS: 24 hour dwell, 6oz/in

- Adhesion to Polypropylene: 24 hour dwell, 13 oz/in

- Tack: 19 oz

- Drop Shear: over 100 hours

- Dielectric Strength: 9700 Volts

- Flammability: Less than 5 seconds

Performance properties tested on an HP Laser Jet 5P. Printed samples of 105000 were laminated to aluminum and allowed to dwell 24 hours before exposure to the indicated environmental conditions. Unless noted, results the same for three methods tested.

Short Term High Service Temperature:

5 minutes at 536°F (280°C) - No visible effect to label at 280°C. Label discolors slights at 300°C but still functional. at 320°C label still functional but slightly discolored and adhesive discolored at label edge.

2 hours at 518°F (270°C) - No visible effect to label at 260°C. Adhesive brown at edge of label at 280°C.

Long Term High Service Temperature:

1000 hours at 356°F (180°C) - No visible effect to label at 180°C. At 200°C label still functional but slightly discolored and adhesive brown at edge. At 200°C laser print degraded.

Low Service Temperature:

1000 hours at -94°F (-70°C) - No visible effect

Humidity Resistance:

1000 hours at 100°F, 95% R.H. - No visible effect

UV Light Resistance:

1000 hours in UV Sunlighter 100 - Topcoat fades to light yellow, label still functional

Weatherability:

1000 hours in Xenon Arc Weatherometer - Topcoat degraded. Not recommended for outdoor use.

Salt Fog Resistance:

30 days at 5% salt fog - No visible effect

Abrasion Resistance:

Taber Abraser, CS-10 grinding wheels, 500 g/arm - Slight topcoat removal but print still legible with R2000 at 200 cycles

Wave Solder and Vapor Phase Resistance:

- Label adhered to epoxy PC Board and exposed to 10 second dip at 480°F (249°C) - no visible effect

- Label adhered to epoxy PC Board and exposed to 2 minutes in Flourinert FC-5312 vapor phase at 420°F (216°C) - Vapor Phrase: R2000 had no visible effect with and without rub. Laser print had no visible effect without rub and severe print smear after rub.

Samples printed with Series R2000 dot ;matrix ribbons and Laser Jet 5P. Samples laminated to aluminum panels and allowed to dwell 24 hours prior to testing. Test was conducted at room temperature except where noted. Testing consisted of 5 cycles of 10 minute immersions in the specified test fluid followed by a 30 minute recovery period. After final immersion, samples rubbed 10 times with cotton swab saturated with test fluid.

- Methyl Ethyl Ketone: Slight adhesive ooze, print bleed without rub, moderate print removal after rub

- 1,1,1-Trichloroethane: Slight adhesive ooze, print bleed without rub, slight print removal after rub

- Toluene: print bleed without rub, moderate print removal after rub

- Isopropyl Alcohol: No visible effect

- Mineral Spirits: No visible effect without rub, slight print removal after rub

- JP-9 Jet Fuel: Slight adhesive ooze, no visible effect without rub, complete print removal after rub

- 6% Alphametals 2110 Saponifier at 70°C: topcoat removed

- SAE 20 WT Oil at 70°C: No visible effect

- Mil 5606 Oil: No visible effect

- Skydrol 500B-4: Moderate print removal without rub, severe print removal after rub

- BIOACT® EC-7R™ Terpene Cleaner: No visible effect without rub, moderate smear after rub

- Axarel® 32: print removed

- Re-entry KNI Solvent 2000 Terpene Cleaner: No visible effect without rub, severe print removal after rub

- Deionized Water: No visible effect

- 3% Alconox® Detergent: No visible effect

- 10% Sodium Hydroxide Solution: Whitening on topcoat

- 10% Sulfuric Acid Solution: No visible effect

105000 is not recommended for use in aqueous cleaning processes.

Samples printed with R2000 dot matrix ribbons and Laser Jet 5P. Printed Labels subjected to 3 cycles of 3 minute immersions immediately followed by a toothbrush rub after each immersion.

- Solvent A, 1 part IPA, 1 part Mineral Spirits: No visible effect on Dot Matrix, print removed on laser jet 5P

- Solvent B, 1,1,1-Trichloroethane: Solvent deleted per Notice 12 on Dot Matrix, Solvent deleted per Notice 12 on Laser jet 5P

- Solvent C, Terpene Defluxer: No visible effect on Dot Matrix, print removed on Laser jet 5P

- Solvent D, Saponifier at 70°C: No visible effect

- Laser printed samples failed test

Product testing, customer feedback, and history of similar products, support a customer performance expectation of at least two years from the date of receipt for this product as long as this product is stored in its original packaging in an environment below 80°F and 60% RH. We are confident that our product will perform well beyond this time frame. However, it remains the responsibility of the user to assess the risk of using suck product. We encourage customers to develop functional testing protocols that will qualify a product's fitness for use in their actual applications.

Mil-Spec Dot Matrix Ribbon List

R2001

C-Itoh CI-300 | DEC6904 | IBM P300, P600, 6408 | Printronix 300P, 600, 3000, 6000, 6080, 9000, L150, L600, L9012 | MPV150, MZP3122, P300, P300 BM1717, P300XQ, P6240, P9012 | Series 60 Z-ICOH C1800 | STD Diagnostic P300 Wallace 300 LPM | Weber Legitronic 50/55/60

R2051

Alps 2000,P2000G | Citizen MSP-15, MSP-15E, MSP-45, MSP-55 | DM2015 | Epson 286E, FX100, FX100+, FX105, FX1050, FX185, FX286 | FX286E, FX 1000, FX 1170, LX1000, MX100, MX1000, MX1003, PX100 | RX100, RX1000, SX1050, Action Printer T-750 | Honeywell Italia 4/21, 4/23 | Olympia MP-136, NP36

R2005

C-Itoh 5800 | DEC LA30-36, LA36 | IBM 1443, 2203, 2560, 2780 | ITT700795-001, Courier 9315 | Texas Instruments 810, 810 in spools | T.I.OMNI 800, 810 | Univac 0798

R2052

Epson 4000, 510, L1000, LQ400, LQ500, LQ510, LQ550 | LQ800, LQ850, LQ570, LQ870, Action Printer 3000, 4000, 5000, LQ800 | Genicom 20/GP20

R2008

DEC LA120,LA180,LA78 | DIGITAL120/180 | Digital DECWriter III Genecom 1795 | Texas Instruments 820 | Teleprinter 1000 | T.I.OMNI 800, 810, 820 RO

R2053

Citizen 224 | Epson Action Printer 4500, 5500, 5550, l750 | LQ1000, LQ1010, LQ1050, LQ1070, LQ1070+, LQ 1170, LX1050

R2012

Centronics 101

R2060

Apple Imagewriter I,II | AT& T471, 473, 474, 476, 580 | C-Itoh 1550, 1550C, 1550SP, 7500, 8500, 8510, 9500, C310, C315, M1550 | Data Products 9030 | DEC 1150, LA50, LA75, LA-75P | IBM 4971, 5533 | Macintosh II | NEC 8023, 8023A, 8025A, LA50 | NCR 6411, 572, 8510 | Telex 281B/C/D | Toshiba Imagewriter I

R2020

Adler SE 1000C | Facit 1850, 1860, 80, 85, 850, 4248 | IBM 82C, TEK 3, Selectric Typewriter, Selectric II 82, 85, 95 | Macintosh Imagewriter | Olympia 6010, 6020, 6510, 6610 | Royal SE 1000C, 6000, 5000C | Triumph Adler

R2065

Okidata 120, 80, 80-82, 82, 8283, 82A, 83, 90, 92, 921, 93 | 93+, U83, U92, U93, UAB-3, Star Delta 10, LV1210, LV1215 | SG10, Gemini 10X | Micronics SG-1015

R2021

IBM5211-1-2-A-B,IBM System 34 Model 1-2, IBM System 38-5211

R2070

BradyWriterT I

R2022

IBMSilver Dollar 3715

R2071

BradyWriter II (24-pin) | Alps 224E, ALQ-224 | Tandy DMT-2100P | Toshiba 1340, 351, P1340, P1350, P1351, P321, P341, P351

R2023

IBM 3262, 5262, IBM 38-4331/5261, IBM 34-3262

R2072

BradyWriter II,III | Okidata 292 | Siemans 9011-18, 9011-28

R2024

BMSilver Dollar 3287, IBM 38-1-2-3, IBM 5320-A, IBM 535

R2080

IBM 2380, 2381, 2390, 2391, PS-PTR-II, SLV-DAT-PTr

R2025

IBM4207, Proprinter 4201,4201-001, 4207, 6328829, II | MT4201-002, X-24 4201, X-24 4207

R2081

Okidata 182, 192, 193, 320, 321

R2050

BradyPrinterTPS | Citizen HSP-500,MSP-10, MSP-20, MSP-50 | Epson Action Printer 2000, 2500, T1000, 3210, 810, 8750F, Apex 80 | FX26E, FX80, FX800, FX85, FX850, FX86, FX86E, FX870, GX80 | LX 300, LX400, LX800, LX810, LX850, MX7080, MX80, MX800 | RX80, SX80, T1000 | Hewlett Packard 82905A, 92156A. Honeywell 4/20 | IBM 5125, M1724, Proprinter 5152 | NCR 7052, 7053, 8750

R2082

Okidata 520, 521

R2083

Panasonic KXP 1150/KXP 1695

R2100

BMCX-Plus

Availability

This product is currently available by special order. Pricing and shipping quotes available on request. Alternative materials may be available in stock. Please contact us for more information.